Splice Insights: The Process

Fenner Dunlop proudly presents

Splice Insights: The Process

By: Buddy Wilson/Senior Director – Service Operations at Fenner Dunlop

By: Buddy Wilson/Senior Director – Service Operations at Fenner Dunlop

Vulcanized splicing is a means in which to join the open ends of a conveyor belt to create one continuous loop. Often times, the means in which a vulcanized splice is executed, is left with little regard from both the customer and the service provider. When this occurs, the overall value and performance of the belt is negatively affected.

Over the years, we have witnessed some customers agonize over choosing the correct belt for their critical conveyor application. Calculations, inspections, guarantees, etc. are exhausted to protect precious uptime and realize the greatest potential lifecycle of the belt. At the same time, the same customer gave very little thought into who would install the belt and make the ever-critical vulcanized splice. This portion of the process is often deemed negligible and hold very little value, which can result in the most critical error. While the quality of the belt is paramount, the quality of the splice is equally critical.

Because the splice is usually the weakest point within the conveyor belt, it must be protected during all stages of operation. The splice must withstand a wide variety of tension ranges. This includes conditions where belt tension may see levels of 150% of rated load. Other conditions include short transitions, “S” drive arrangements and shock loads.

At Fenner Dunlop, we believe conveyor belt manufacturers should lead the way in determining all splicing processes and procedures for their belting products. Our splicing procedures are incorporated with our ISO 9001:2015 certification. By taking this step, we can match our conveyor belting designs to specific splicing procedures to deliver ultimate value and performance to the customer. The belting manufacturer you chose for your critical applications, at a minimum, should always provide this support.

Splicing procedures (processes) are purposely detailed to remove any opportunity for conjecture. The process includes Health & Safety, Tooling & Equipment, Materials, Laying Out of Belt Ends, Stepping & Preparing, Splice Assembly and Curing. With this in mind, let’s explore some specific process points that are critical, and often overlooked or ignored.

Splice Layout:

Splice layout and design are specific dimensions as determined by the belt manufacturer. These dimensions are chosen by conveyor belting engineers and technical personnel to ensure the best possible performance and longevity of the belt. Despite having written procedures available, many service providers default to what could be described as “generally accepted dimensions” when it comes to laying out and preparing the splice.

While this could work, it is not recommended. The notion of “short-stepping” or shortening of fingers is usually tied to two underlying issues. The first is lack of proper equipment and the second it to save time. Regardless of the reason, these shortcuts can, and have negatively affected the performance of conveyor belting. Additionally, this neglect in the written process only perpetuates a lack of value in premium belting and premium service within the market.

Edge Irons:

In the manufacture of any conveyor belt, edge irons or edge bars are used to brace the belt edges under pressure, which allows for optimum pressure to be distributed all the way to the belt edge. By utilizing edge irons, maximum adhesions can be achieved throughout the entire belt. The same is true for vulcanized splicing. The utilization of edge irons become even more paramount as the belt has been stripped out, and then reassembled.

While it may seem logical, many service providers often utilize old belt to pad the edges or skip the step completely. Either method reduces the amount of pressure that can be contained within the splice during the curing process. This leads to blisters, air pockets, edge porosity and overall lack of adhesion within the splice. The proper use of edge irons is a key step in executing a proper vulcanized splice.

Time, Temperature & Pressure:

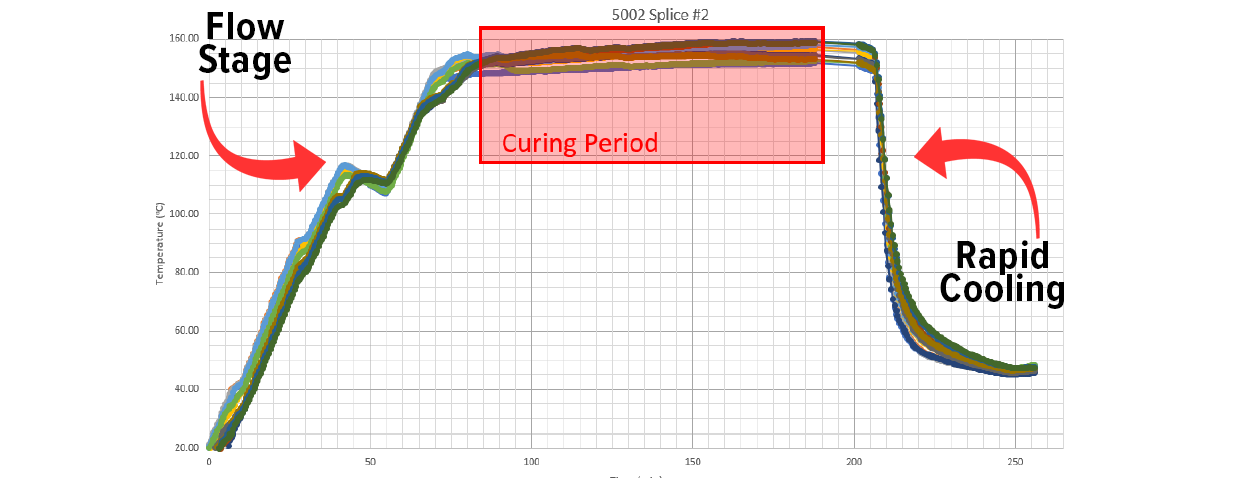

When considering the cure process, time, temperature and pressure must be applied correctly. Lack of pressure and time can lead to an under-cured splice. Too much heat and time can lead to an over-cured condition – sometimes even resulting in a glass state. Delayed cooling, sometimes referred to as “air cooling”, can also lead to an over-cured condition.

Another common mistake is ignoring the required flow period during the curing process. This step is critical to allow for optimal material penetration and migration though the structure of the splice. See the below representation graphic of a proper curing cycle.

The last point is that cooling the splice rapidly is the preferred method. Air-cooling prolongs the cure time and can have detrimental effects on the quality of the splice.

In the next part of Splice Insights, we will be exploring the value and importance of splice workmanship. Follow us on social media to stay updated when new blog posts become available and click the subscribe button in the bottom right corner on your screen.

Find your local distributor or Fenner Dunlop Conveyor Services location by checking out our interactive map here or reach out to us at info@fennerdunlop.com if you have any questions about vulcanized splicing!