Nova-X®

Our UsFlex® and Nova-X® carcasses can handle the toughest aggregates applications from sand and gravel to primary crushers where premium products are required. UsFlex and Nova-X offer unsurpassed impact and puncture resistance, excellent load support, and longer service life than other premium belts.

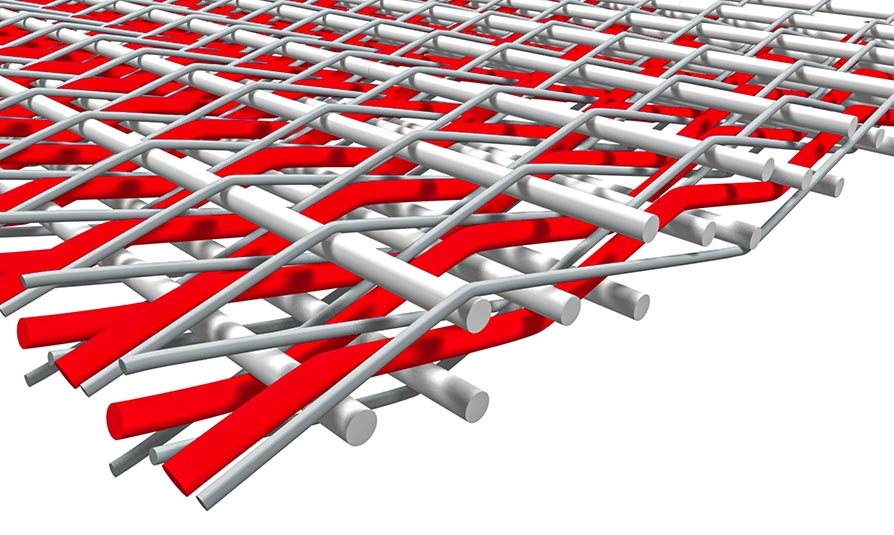

NOVA-X

- Patented dual crimp weave for higher strength and low stretch applications

- Unique fabric weave allows for improved mechanical fastener retention & splice life

- Smaller gauge carcass allows for smaller diameter pulleys, as well as superior troughability, tracking and load support

- Nova Xtreme discover the innovative carcass designed specifically for high heat applications

Convey bulk materials more reliably with this advanced flexible belt core

Excellent resistance to rips, tears, impacts, and punctures using a technologically advanced and patented belt fabric design

Available Cover Compounds

Nova-X® is available in cover gauges up to 1/4” and in the following compound:

Select interesting properties to get detailed information.

-

ZR1

Exhibits excellent tensile… Exhibits excellent tensile and abrasion resistance. Good resistance to cutting and gouging. Great in extreme… Exhibits excellent tensile and abrasion resistance. Good resistance to cutting and gouging. Great in extreme temperatures.

- Abrasion

- Cold

- Cut/Gouge

-

Titanium

Provides increased service… Provides increased service life without increasing cover thickness. Exhibits excellent abrasion-resistant characteristics. Compliant with DIN… Provides increased service life without increasing cover thickness. Exhibits excellent abrasion-resistant characteristics. Compliant with DIN Standard “Y” Recommended for application requiring superior resistance to abrasion and wear, outstanding in high impact applications. Best for abrasion resistance Get more life with less cover thickness…

- Abrasion

- Cut/Gouge

-

ZR3

Offers the absolute… Offers the absolute best resistance to heavy, continuous abrasion. Increased service life without increasing cover… Offers the absolute best resistance to heavy, continuous abrasion. Increased service life without increasing cover thickness. Exhibits excellent tensile and superior abrasion resistance. Good resistance to cutting and gouging + frigid temperatures.

- Abrasion

- Cut/Gouge

-

Matchless

Matchless (RMA Grade… Matchless (RMA Grade 1) Superior endurance against combined cutting, gouging and heavy impact. Recommended for… Matchless (RMA Grade 1) Superior endurance against combined cutting, gouging and heavy impact. Recommended for transporting large, heavy lump ores, rocky earth, granite, trap rock and quartz. Unequalled in conveying heavy logs from debarker. Good abrasion resistance. Superb for glass cullet handling and other types…

- Abrasion

- Cut/Gouge

-

Matchless Plus

Provides the same… Provides the same features of Matchless, but with approximately 15% greater service life. Compounded for… Provides the same features of Matchless, but with approximately 15% greater service life. Compounded for the most severe cut, gouge and impact applications.

- Abrasion

- Cut/Gouge

-

ORP

(Oil Resistant Plus)… (Oil Resistant Plus) Superior resistance to materials containing high concentrations of animal fats and oils. (Oil Resistant Plus) Superior resistance to materials containing high concentrations of animal fats and oils. Recommended for use involving heavy exposure to aromatic hydrocarbons such as petroleum-based oily coke, benzol, and toluene.

- Oil

-

Sahara SAR

Top fire retardant… Top fire retardant and heat resistant product… Top fire retardant and heat resistant product…

- Abrasion

- Heat

-

ORWP

Oil Resistant (OR)… Oil Resistant (OR) Wood Products Resists deteriorating effects or terpenes. Ideal for lumber and wood… Oil Resistant (OR) Wood Products Resists deteriorating effects or terpenes. Ideal for lumber and wood chip handling.

- Oil

-

MOR

Recommended for specialized… Recommended for specialized services such as wood chips, whole grains like corn and soybeans, waste… Recommended for specialized services such as wood chips, whole grains like corn and soybeans, waste disposal, sewage, sludge and lightly treated materials. Resistant to the deteriorating effects of moderately oily materials and terpenes.

- Oil

-

Granite

Excellent where heavy,… Excellent where heavy, continuous abrasion is the primary concern. Good resistance to cutting and gouging. Excellent where heavy, continuous abrasion is the primary concern. Good resistance to cutting and gouging. Recommended for most above-ground abrasive material handling applications, such as coal, coal mine refuse, crushed ores and rock, slag, limestone, potash, trona, salt, sand, aggregate and other abrasives.

- Abrasion

-

Platinum

Good abrasion resistance. Good abrasion resistance. Good endurance against combined cutting, gouging and heavy impact. Recommended for transporting… Good abrasion resistance. Good endurance against combined cutting, gouging and heavy impact. Recommended for transporting large, heavy lump ores, granite, and trap rock.

- Abrasion

- Cut/Gouge

-

Guardian AR

High quality grade… High quality grade II fire retardant compound specifically designed to counter the negative effects of… High quality grade II fire retardant compound specifically designed to counter the negative effects of leaching agents as well as dust suppressants. Meets MSHA 2-G requirements. Excellent abrasion and cover wear characteristics. Recommended for Power Generation facilities and Coal Prep Plants

- Abrasion

- Fire

-

CWOR

Outstanding resistance to… Outstanding resistance to the very difficult combined effects of cold, abrasion and petroleum products. Cold… Outstanding resistance to the very difficult combined effects of cold, abrasion and petroleum products. Cold Weather Temperature resistance to -50F. Recommended for conveying tar sands, bitumen, oil sprayed coal and similar materials.

- Cold

- Oil

-

Guardian OR

Specifically designed to… Specifically designed to counter the negative effects of leaching agents as well as dust suppressants. Specifically designed to counter the negative effects of leaching agents as well as dust suppressants. Meets MSHA 2-G requirements. Increased resistance to abrasion and cover wear. Medium oil resistance where oil resistance is required. Recommended for power generation facilities and coal prep plants.

- Fire

- Oil

-

MOR E

Excellent abrasion-resistant cover… Excellent abrasion-resistant cover with outstanding resistance to the deteriorating effects of moderately oily materials and… Excellent abrasion-resistant cover with outstanding resistance to the deteriorating effects of moderately oily materials and terpenes. Increased oil resistant properties, recommended for specialized services such as wood chips, whole grains such as corn and soybeans, waste disposal, sewage, sludge and lightly oil-treated materials.

- Low extraction

- Oil

-

Platinum Plus

ARPM Grade 1… ARPM Grade 1 compound recommended for transporting large, heavy lump ores, granite, and trap rock. ARPM Grade 1 compound recommended for transporting large, heavy lump ores, granite, and trap rock. Also compliant with DIN X standards.

- Cut/Gouge

-

Sahara FR

Offers performance in… Offers performance in extreme hot material applications. Designed for hot exposure of limited duration up… Offers performance in extreme hot material applications. Designed for hot exposure of limited duration up to 1000F without risk of melting or fire.

- Fire

-

DeltaHeat 2.0

Delta Heat® 2.0… Delta Heat® 2.0 is Fenner Dunlop’s new and improved premium hot material compound designed to… Delta Heat® 2.0 is Fenner Dunlop’s new and improved premium hot material compound designed to resist the negative effects of cover cracking, hardening, flexing, tearing and abrasion associated with high-temperature environments. Delta Heat® 2.0 Temperature resistant to 400°F (205° C) for abrasive coarse lumps (2…

- Abrasion

- Heat

- Low extraction

-

DIN-X

DIN X compliant… DIN X compliant cover DIN X compliant cover

- Abrasion

-

Sahara OR

Excellent resistance to… Excellent resistance to oil and heat up to 300° F (150°C) temperatures for coarse lumps… Excellent resistance to oil and heat up to 300° F (150°C) temperatures for coarse lumps (2″ or + 50mm in size) and 250° F (120° C) for abrasive fines as well as for low-temperature applications down to (-55° C) Recommended for conveying hot mixtures containing…

- Heat

- Oil

-

CGH 2.0

Moderate oil resistant… Moderate oil resistant covers for grain handling. Compounded for colder operating climates. The temperature range… Moderate oil resistant covers for grain handling. Compounded for colder operating climates. The temperature range -40 to 200F Surpasses U.S. Occupational Safety and Health Administration specifications for static conductivity. CGH Cover Compound is also fame retardant per MSHA Title 30, Section 18.65 requirements. Electrical resistance…

- Fire

- Oil

-

UGH 2.0

Provides maximum oil… Provides maximum oil resistance to the destructive effects of grain oils and oil-based dust suppressant… Provides maximum oil resistance to the destructive effects of grain oils and oil-based dust suppressant additives. Temperature range -30°F – 180°F. Surpass U.S occupational safety and Health Administration specifications for static conductivity. The cover is also flame retardant per MSHA Title 30, section 18.65 requirements.

- Fire

- Oil

-

DIN-K

DIN K compliant… DIN K compliant cover DIN K compliant cover

- Abrasion

-

Guardian SAR

ARPM Grade I… ARPM Grade I Fire retardant abrasion resistant compound that meets ARPM-FR Class 2 High-quality Grade… ARPM Grade I Fire retardant abrasion resistant compound that meets ARPM-FR Class 2 High-quality Grade I fire retardant compound specifically designed to counter the negative effects of leaching agents as well as dust suppressants. •Excellent abrasion and cover wear characteristics. •Recommended for Power Generation Facilities…

- Abrasion

- Fire

-

ZR2 ORB

Resists combined effects… Resists combined effects of cold, abrasion and petroleum or oil based products Cold weather resistance… Resists combined effects of cold, abrasion and petroleum or oil based products Cold weather resistance to -50° F (-46° C) Great for conveying oil sands, bitumen, oil-sprayed coal and similar materials…

- Abrasion

- Cold

- Oil

-

Giant XE

High durability recipe… High durability recipe offering resistance to dedusting agents or hygroscopic materials. A Premium compound that… High durability recipe offering resistance to dedusting agents or hygroscopic materials. A Premium compound that meets all ARPM Grade 1 specifications, suitable for applications such as cement, aggregates, rock, copper, gold, limestone, potash and salt. Ideal for heavy and abrasive materials and specially designed for…

- Abrasion

- Cut/Gouge

-

Guardian HF

High-quality grade II… High-quality grade II fire retardant compound. Compounded to be Halogen (Chlorine) free. Recommended for Power… High-quality grade II fire retardant compound. Compounded to be Halogen (Chlorine) free. Recommended for Power Generation facilities and Coal Prep Plants.

- Fire

-

Alumina

A special compound… A special compound designed to offer resistance to heat, abrasion, and the impact of Alumina… A special compound designed to offer resistance to heat, abrasion, and the impact of Alumina on the long term rubber compound properties. Heat resistant to 200° F for fine material.

- Abrasion

-

Guardian ORX

Provides maximum oil… Provides maximum oil resistance. Temperature range -30°F – 180°F. Surpass U.S occupational safety and Health… Provides maximum oil resistance. Temperature range -30°F – 180°F. Surpass U.S occupational safety and Health Administration specifications for static conductivity. The cover is also flame retardant per MSHA Title 30, section 18.65 requirements.

- Fire

-

Sahara DS

Provides good abrasion… Provides good abrasion resistance in elevated operating temperature environments. Temperature resistant to 300 deg F… Provides good abrasion resistance in elevated operating temperature environments. Temperature resistant to 300 deg F (149 deg C) for abrasive coarse lumps ( 2 inches +/50 mm +) and 250 deg F (120 deg C) for abrasive fines.

- Abrasion

- Heat

- Low extraction

-

Granite (LM)

Excellent where heavy,… Excellent where heavy, continuous abrasion is the primary concern. Good resistance to cutting and gouging. Excellent where heavy, continuous abrasion is the primary concern. Good resistance to cutting and gouging. Recommended for most above-ground abrasive material handling applications, such as coal, coal mine refuse, crushed ores and rock, slag, limestone, potash, trona, salt, sand, aggregate and other abrasives.

- Abrasion

-

Power Saver (Bottom Cover)

Low Rolling Resistant… Low Rolling Resistant bottom cover option for flat and low incline belts. Energy-saving. Sustainability. Low Rolling Resistant bottom cover option for flat and low incline belts. Energy-saving. Sustainability.

- Power Saver